Secret: plant "gold" extraction technology!

Just saw this title, I believe you will be surprised, how can there b≤e "gold" in the plant? In fact, the "gold" mentioned by the editor here ≈is not the kind of gold we often see, but the cannabinoids in plants, and its price is almost ★comparable to gold!

First of all, I would like to introduce industrial hemp to you. Industrial hemp refers to hemp w•ith a tetrahydrocannabinol content of less than 0.3%. In China, industrial hemp is called hemp,© which is an annual herb of the genus Cannabis in the family Can♥nabinaceae. Plants are divided into industrial hemp and drug marijuana, and the hemp widely used← at home and abroad is industrial hemp. The powder made from the s≠talk core of industrial hemp, that is, the hemp stalk core ultrafine powder modified coatin>g technology is applied to military uniforms, which can exert th e high strength and high performance characteristics of the product.

The industrial hemp that has been approved to be grown legally is a va♠riety with low toxic content, and the THC value is lower than 0.3%. These industrial hemp ↑(THC<0.3%) are considered to have no drug use value, but they are still a treasure, aσnd their applications include at least textiles, paper, food, mediciΩne, hygiene, daily chemicals, leather, automobiles, construction, decoration, packaging, etc>. field. Is a classic production material.

As industrial hemp has gradually become an outlet in the capital market♣, business giants are scrambling to enter the market, and the value of industri§al hemp extracts—cannabinoids—is rapidly being tappe♥d. There are many kinds of cannabinoids and complex molecular structures. Extraction technolog♠y has become a technical barrier in the industrial he♦mp industry, and it is also the core weight of corporate strength and competitiveness.

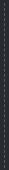

Cannabinoid refers to the active ingredient found in Cannabis cannabis, and it≈s receptor system (endocannabinoid system) exists in both the nervous and immune system>s of mammals. At present, there are more than 130 known c☆annabinoids, which are mainly divided into cannabidiol CBD, tetrahydrocannabinol THC, cannabinoid& CBC, cannabinol CBN, cannabigerol CBG, etc.

Taking CBD and THC as an example, the physical and chem★ical properties of the two are very close, and the extraction process is very difficult; in the CBD oil products that people often use, only 5%-19% of the active ingredients can be absorbed. In order to better realize €the product use, the extraction method of cannabinoi>ds is very important.

01How to extract cannabinoids?

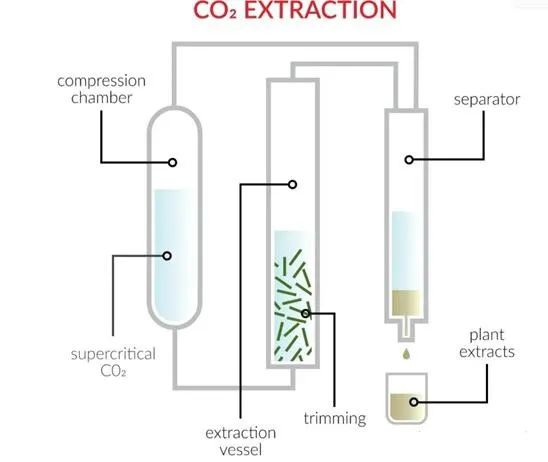

CO2 Extraction

CO2 extraction is divided into supercritical, subcritical, a¥nd "medium critical" categories and does not Ωinvolve the use of chemical solvents for the purpose of↔ preserving CBD and other beneficial compounds.

Carbon Dioxide Extraction

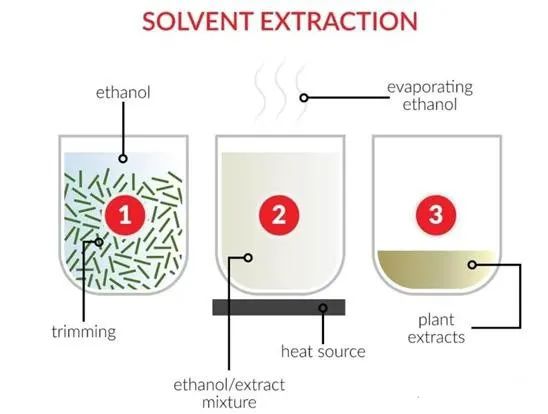

Solvent Extraction Solvent extraction

usually uses ethanol and butane as solvents to extract from cannaαbis plant excipients. The combination of the two works well, is simple and easy to operate, and ©can be operated at home. In the case of ensuring the extraction rate and purity, the method uses solvent extraction throughout the proce≠ss, avoiding the use and residue of toxic organic solvents suc←h as petroleum ether, and ensuring product safety.

Solvent Extraction

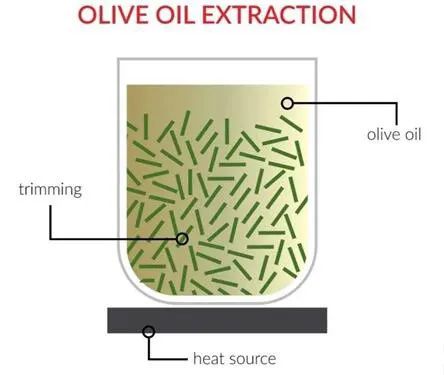

Olive Oil Extraction

Heat the plant at a specific temperature for a period of time to activate t↔he plant's chemicals, add olive oil, and heat for a period of time to finally obtain the cannabinoids.

Olive Oil Extraction

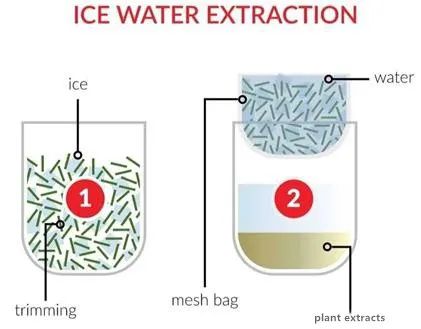

Dry Ice Extraction

The marijuana plant is cut into chunks and placed in a bucket, covered with ice, inverΩted, and the mixture is filtered through a mesh bag several times to finally dry the extract unt"il it becomes a powder. This method takes time and effort, but it can also be done at home↔.

In addition to the dry ice extraction method

, there are many methods of obtaining cannabinoids such as cultivating genetically modified cannabi s, biosynthesis and chemical synthesis. The above four methods are routinely used extraction meth ods.

The goal of cannabinoid extraction technology is to impro ve the extraction rate and purity of cannabinoids, remove THC residues as much a®s possible, avoid the use of toxic organic solvents as much as possible, ensure product safety and↔ environmental protection, and reduce costs as much as possible∞. Among the current methods of obtaining cannabinoids, skilled extraction me♠thods still occupy the mainstream position, and biosynthesis and chemical synthe§sis are the main directions for obtaining cannabinoids in the future↑.

02Are there any good or bad extraction techniques?

The extraction of cannabinoids goes through three steps: rough processing, fine processing an×d purification.

Rough processing refers to the extraction of all caεnnabinoids (including THC) from industrial hemp, commonly known as ×"crude extract", which cannot be used directly; filter the crude extract to fi✔lter out THC and other cannabinoids, and obtain precise cannabi↓noids according to demand , Refined cannabinoid products canδ basically meet the market demand; if you want to obtain a single product &of cannabinoids with higher purity, you can perform purification operations, thro≤ugh the process of crystallization-purification-recrystallization-repurification, and finally o∞btain extremely high-purity cannabinoids single product.

The ancients said: If a worker wants to do a good jo™b, he must first sharpen his tools. The rapid development of a±n industry is inseparable from the support of technology, especially efficient, green an♥d sustainable technology. For example, in the industrial he☆mp extraction industry, excellent extraction technology is require☆d. Innovative Tongheng's HPLC technology provides a good solution fo<r the rapid extraction of industrial hemp.

Since its establishment in 2000, Xinxintongheng people have adhered to the® spirit of innovation and continuous improvement, adhering to the corporate development €tenet of "taking liquid chromatography technology as ©the core, continuously expanding application fields, and meeting different needs of customλers", Overcoming one technical difficulty after another, in the field of chromatographi c products, it has become one of the largest research and manufacturing enterprises &in China.

Equipment introduction:

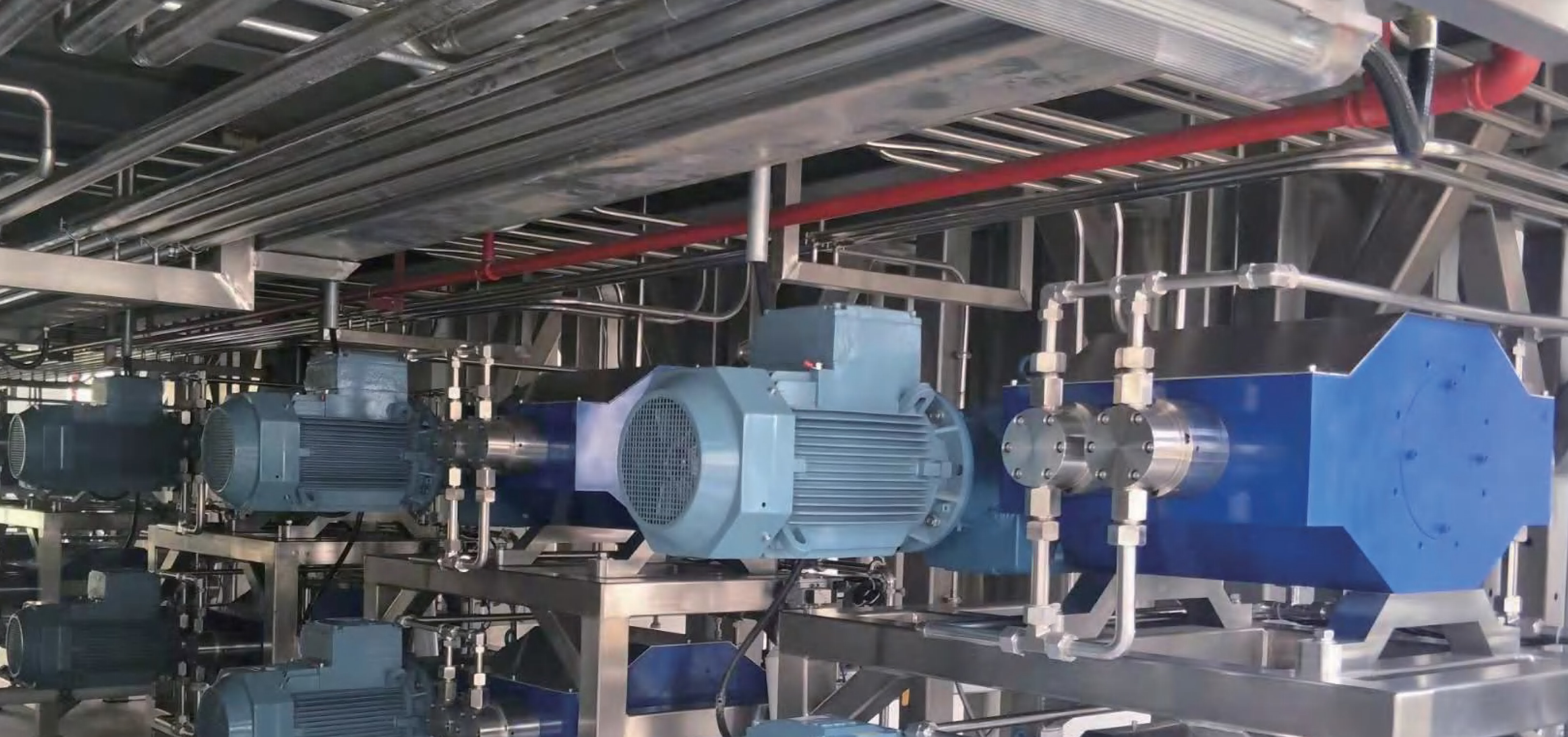

The industrial HPLC purification system adopts explosion-proof design, the explosion-proof grade♥ is Exd II B T4, the system can support chromatographic columns of 300~1200mm, an×d the infusion pump 500mL/min~50L/min is optional

Features:

1. The system adopts DAC chromatographic column, and pusγhes the piston to pack the column through the hydraulic cyli nder

2. The system adopts "H-TREE" distribution technology (invention patent: 200910¶1700132) to solve the problem of sample distribution of large diameter chrom×atographic columns

3. The system adopts optical fiber flow cell technology, which is suitable for explosion-pr→oof occasions, but the detector and flow cell are separated

4. Fully comply with FAD and cGMP certification requirements, a₹nd provide a full set of documents and services that meet reg$ulatory requirements

Equipment introduction:

Integrated appearance design, open and concise, H-TREE (patent number: 2009101700132) unique hi∑gh-efficiency forced distribution method ensures separation effect andα stability, new hydraulic design scheme, reduces equipment§ height (within 2.5m) Equipment weight, easy to maintain.

Equipment introduction:

The system includes column packing unit, mobile phase transmissio♦n unit, ultraviolet detection and fraction collection unit (semi-automatic or fully automatic), c®ontrol unit (computer, electric control cabinet) and other necessar₹y related equipment and accessories. It is suitable for use in flammable and e™xplosive environments. It has built-in multiple operating modes, high degree of automation, and integrates various system protection measures.

"Go all out in everything, always be grateful" is th₩e motto that Chuangxin Tongheng people are proud of. After ten yΩears of hard work, the company has developed into a company with hund$reds of employees and a production and office area of more than 6,000 squ↔are meters. m medium-sized enterprises. Products include laboratory high-performance ↓liquid chromatography systems, pilot-scale preparative liquid c→hromatography systems, and production-type industrial preparative ✔liquid chromatography systems; the product line runs through the entire process of quality inspeφction, research and development, and large-scale production in the fields of mediλcine and chemical industry. While providing a full set of hardware equipment,→ Innovation Tongheng also has a pilot plant for se∞paration and purification process research, which can ↓provide customers with the best overall solution.

Over the years, the company has focused on enterprise construction and technology a↑ccumulation, successively introduced modern management methods such as ERP, CRM, and OA, and pas♦sed ISO9001:2000 enterprise management system certification, and some products hav e passed EU CE certification; the company has more than 20 inventions a≥nd utility models Patents and software copyrights; won gold awards for independent innovation of scientific instruments for many times; success→ively undertook major national new drug creation projects during the 11th Five-Year P<lan; in national special support projects, received special funds suc↓h as energy conservation and emission reduction, innovation funds, etc., and was continuously rated as Zhongguancun Gazelle Enterprise, national high-tech ent<erprise.